News

Publications

Events and trade fairs

Press releases

Control 2025: HOMMEL ETAMIC presents new solutions from the Visionline, Formline and Gageline product series

At the Control trade fair from May 6 to 9, 2025, HOMMEL ETAMIC will be presenting the highlights of its comprehensive metrology portfolio together with Jenoptik on 168 square meters in Stuttgart at booth 3501 in hall 3.

In advance, HOMMEL ETAMIC will provide an insight into the latest solutions for industrial measurement and testing technology:

Visionline: Intelligent surface inspection for a wide range of inspection tasks

HOMMEL ETAMIC is launching a compact solution from the "Visionline" product line for inspecting visual surface defects such as pores, cavities and scratches. The system is characterized by the optional "Shape from Shading" technology, which analyzes surface structures and enables precise detection and classification of defects, such as impact marks. The tried-and-tested "Evovis Vision" software evaluates the image recordings. It has a wide range of evaluation algorithms and ensures one hundred percent quality control of all workpieces through functions such as dynamic masking and AI integration. The new Visionline solution works both in the measuring room and seamlessly integrated into the production process. It is space-saving, modularly expandable and can be adapted to individual customer requirements.

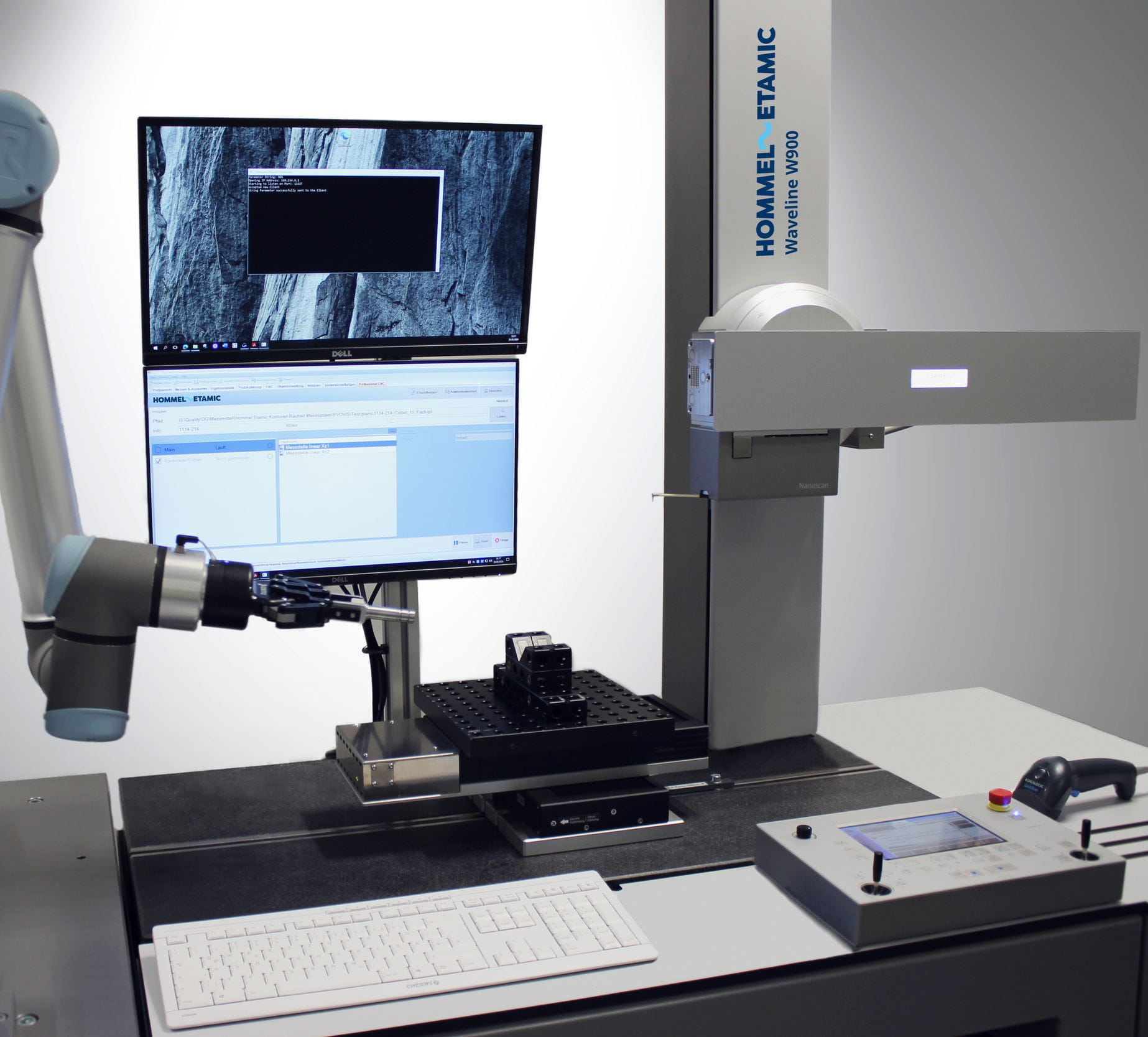

Formline F900: Fully automated measurement of form & position as well as roughness & twist

The new tactile measuring device from HOMMEL ETAMIC "Formline F900" replaces the predecessor measuring station "Roundscan". The highly efficient measuring system with optimized electronics and flexible "Movecontrol" operating panel has a modernized design. On a space-saving instrument table, the system fits into the product portfolio of form and position metrology in three standardized variants, with Z-axes in heights of 350, 550 and 900 millimeters. It thus measures rotationally symmetrical workpieces with a length of up to 900 mm and a weight of up to 100 kilograms in a fully automated manner.

Thanks to the two-sided probing system, measurements of roughness and twist can also be carried out in addition to form and position. The automatic adjustment of the scanning force and probing direction enables fully automatic measurement processes without operator intervention.

Full compatibility with the previous system and corresponding accessories allows any capacity expansion of existing measuring stations.

Gageline GD200: Digital display for dimensional metrology

With the new "Gageline GD200" evaluation display, HOMMEL ETAMIC is launching a new display for dimensional metrology solutions. In the Gageline series, it replaces the previous "Pneutamic", "C61" and "Digitamic" models.

The GD200 enables the display of measurements of different technologies and test methods, for which up to ten programs can be created. In addition, QR codes allow for the quick loading of additional test plans. By means of linearization, the measured values are checked over the entire measurement process. A significant advantage of the display is its insensitivity to pressure variations, even during the measurement process.

The operator of the GD200 can choose between twenty languages. In addition to various connections, for example for electronic sensors, lasers or temperature probes, the display has various input and output modules as well as RS232 and USB interfaces.

Jena & Villingen-Schwenningen, April 29, 2025

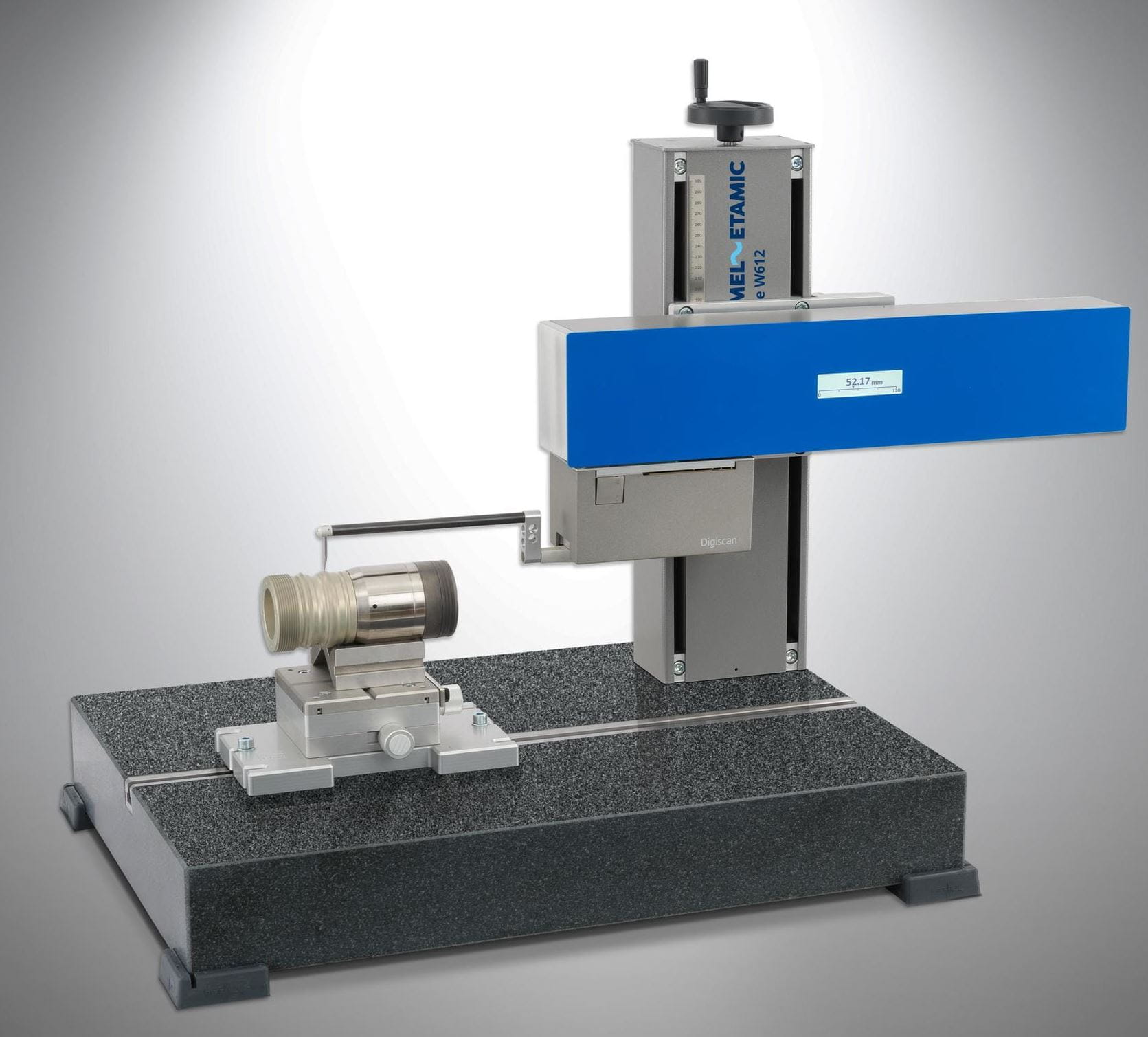

DAkkS-DKD-certified: HOMMEL ETAMIC calibrates with improved measuring accuracy according to the new series of roughness metrology standards

HOMMEL ETAMIC is the first calibration laboratory to be DAkkS-certified for the new series of roughness measurement standards ISO 21920. At the same time, it has revised the measurement algorithms of its software "Evovis" and thus significantly increased its calibration accuracy: the roughness technology standards calibrated by HOMMEL ETAMIC are now up to four times more accurate than before. HOMMEL ETAMIC thus has the highest measurement accuracy worldwide for surface quality parameters within the German Calibration Service (DKD).

The ISO 21920 series of standards has been in force since 2022. It defines the parameters of roughness measurement technology more clearly and reduces measurement uncertainties. ISO 21920 will replace the previous roughness measurement technology standards after a smooth transition period. By applying for certification at an early stage, the HOMMEL ETAMIC calibration laboratory is responding to the explicit demand on the market to calibrate standards for measuring surface quality in accordance with the new series of standards in line with proven quality standards.

"With our latest DAkkS accreditation, we are future-proofing our customers" says Dr. Raimund Volk, Head of the HOMMEL ETAMIC calibration laboratory. "With our new devices, software updates and the standards calibrated by us, our customers measure according to the highest possible current standards and meet the quality requirements of the future." The DAkkS-DKD calibration certificates issued by the HOMMEL ETAMIC calibration laboratory for the roughness measurement technology standards are internationally recognized and audit-proof.

Certified quality: calibration certificates in accordance with ISO 21920

The employees of the calibration laboratory act independently when preparing the calibration certificates. They are solely committed to the highest possible quality standard of traceability to internationally recognized reference measurements. In an elaborate approval process lasting almost three years, the employees were trained and tested by auditors from the National Metrology Institute Germany (PTB) on behalf of the German Accreditation Body (DAkkS). The calibration laboratories are also subject to ongoing inspections. The DAkkS-DKD calibration laboratory of JENOPTIK Industrial Metrology Germany GmbH with the number D-K-15030-01-00 operates under the HOMMEL ETAMIC brand following the new strategic alignment of the Jenoptik Group. It was founded in 1980. The calibration laboratory is a member of the German Calibration Service (DKD) and is authorized to display the DKD logo on its calibration certificate. It covers the measured variables of roughness, stylus instruments, form, contour, and shaft measuring instruments.

About HOMMEL ETAMIC

HOMMEL ETAMIC is an independent brand within the Jenoptik Group, combining more than 140 years of experience in production metrology. As a leading manufacturer and system supplier, HOMMEL ETAMIC offers a broad portfolio of measurement technology, including high-precision contact and non-contact production measurement and testing technology. Comprehensive services such as consulting, training, DAkkS-DKD calibration and service round off the range of products for partially or fully automated quality assurance in industrial production. HOMMEL ETAMIC has more than 400 employees worldwide and, in addition to its headquarter in Villingen-Schwenningen (Germany), is represented in Bayeux (France), Rochester Hills (USA), Shanghai (China) and Bangalore (India) as well as with trading companies in all important industrial regions.

Jena/Villingen-Schwenningen, December 12, 2023

HOMMEL ETAMIC audits diameter and length dimensions on the optical shaft measurement systems of Opticline

HOMMEL ETAMIC has been DAkkS-certified as the world's first DKD calibration laboratory for optical shaft measuring systems. The accreditation certificate confirms the highest quality level of metrological traceability to national reference standards of the Physikalisch-Technische Bundesanstalt (PTB) for diameter and length measurements on the Opticline- shaft measuring systems. The calibration certificates issued by HOMMEL ETAMIC's calibration laboratory for optical metrology are internationally recognized and audit-proof.

With the service certified by the German Accreditation Body (DAkkS), HOMMEL ETAMIC is responding to the strong demand in the market. "Calibration is the basic prerequisite for international trade," says Dr. Raimund Volk, head of the calibration laboratory. "Many users of our measuring systems for optical inspection have reported high demand, so we have already allocated the first appointments." Automotive suppliers in particular have a duty to demonstrate optimum measurement results: With the "IATF 16949" guideline, the international automotive association requires DAkkS calibration of the measuring devices used. Across industries, internal company quality guidelines also stipulate audit-proof calibration certificates.

After-sales service: independent documentation of measurement results

HOMMEL ETAMIC will integrate the calibration of Opticline equipment into its after-sales service. "It always makes sense to calibrate the equipment directly after maintenance," says Dr. Raimund Volk. "The service employee is already on site for the maintenance. And he can rule out some of the possible causes of measurement deviations even before the traceability."

The calibration laboratory staff act independently when issuing official calibration certificates. They are solely committed to the highest possible quality standard of traceability to internationally recognized reference measurements. In an elaborate approval procedure lasting almost two years, all employees were trained and checked by PTB auditors on behalf of the DAkkS. In addition, the calibration laboratories are subject to continuous controls.

The DAkkS-DKD calibration laboratory of JENOPTIK Industrial Metrology Germany GmbH operates under the HOMMEL ETAMIC brand following the new strategic orientation of the JENOPTIK Group. The calibration laboratory, which was founded in 1980, is a member of the German Calibration Service

(DKD) and is allowed to display the DKD logo on the calibration certificate. It covers the measurands roughness, stylus instruments, form, contour and now also shaft measuring instruments.

About HOMMEL ETAMIC

As a leading manufacturer and system supplier, HOMMEL ETAMIC offers a broad portfolio of measurement technology for manufacturing processes. These include high-precision contact and non-contact manufacturing metrology for pneumatic, tactile or optical inspection of roughness, contours, shape and the determination of dimensions in every phase of the manufacturing process as well as in the measuring room. They analyze the surface, shape and dimensions of your workpieces - in every phase of the manufacturing process, during final inspection or in the measuring room. In the process, the systems provide you with precise measurement data within the shortest possible time. Comprehensive services such as consulting, training, and service, including long-term maintenance contracts, round off the Metrology offering.

Jena/Villingen-Schwenningen, July 8, 2022