Surface roughness and contour metrology

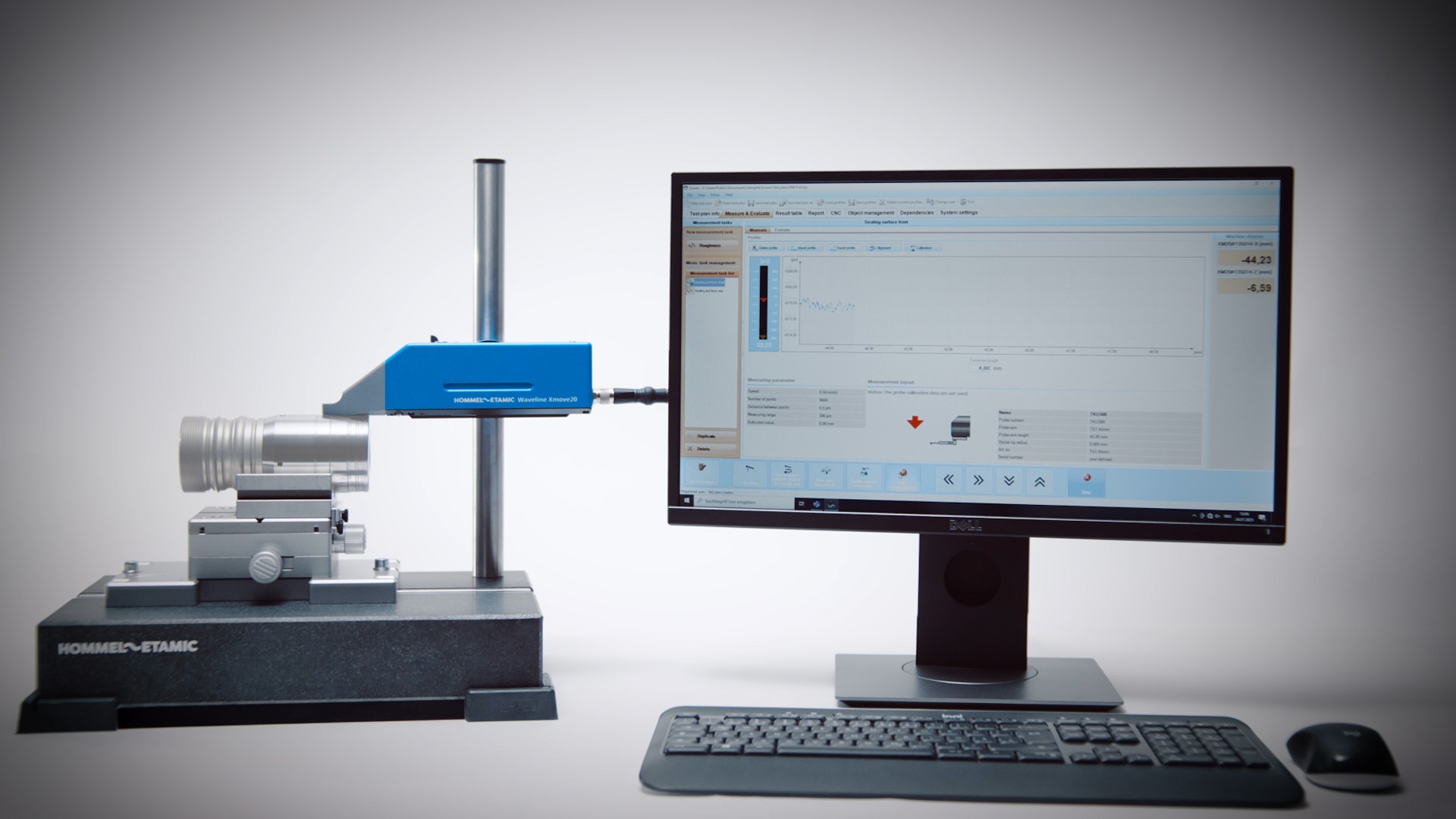

Waveline measuring systems offer you numerous evaluation options in the field of mobile and stationary surface measurement.

Our product range consists of mobile surface measuring instruments, stationary measuring systems for manual and automated roughness, contour, topography or twist measurement, as well as combined systems for roughness and contour measurements. We also offer measuring stations tailored to your specific measuring requirements.

Waveline solutions are the result of our years of experience and comprehensive know-how and can be configured for different measuring tasks depending on the requirements.

Our measuring systems operate with high precision and reliability in accordance with current standards. They are easy to operate and are ideally suited for daily use on the shop floor and in the metrology lab.

Wide range of roughness measuring instruments

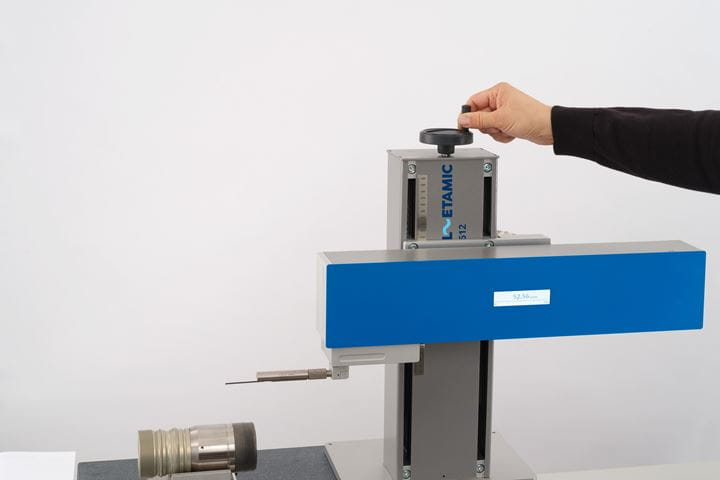

Waveline W40

Waveline W900 Wavemove

Mobile surface roughness measurement

Whether on the shop floor, on the production line or in the metrology lab, our mobile surface measuring instruments are the ideal partner for reliable and precise measurements. With their functional design, the devices fit securely in the hand and are positioned precisely on the workpiece.

With various probes and a large range of accessories, they master the most diverse measuring tasks with ease. In terms of accuracy, they are in no way inferior to stationary measuring systems.

Benefits

- High precision: Precise and reliable measurement

- Versatile: Mobile and stationary measuring instruments for different measuring tasks

- Compliant with standards: Meet the strict requirements of international standards

- Easy to use: Intuitive state-of-the-art technology and user-friendly software

Waveline W5 with printer

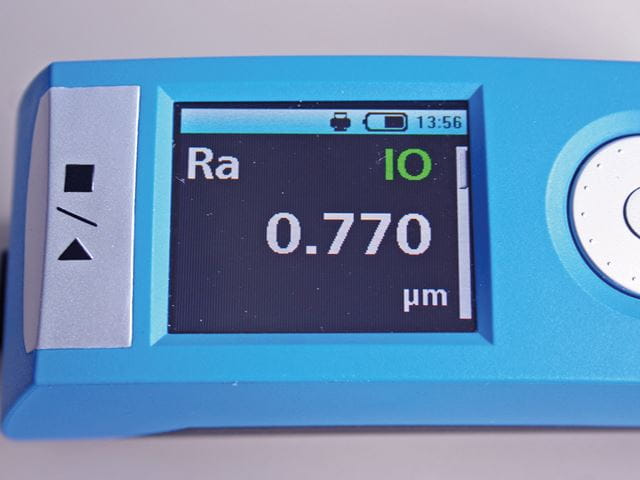

The mobile roughness measuring instrument Waveline W5 convinces with safe and highly precise roughness measurement. The system is positioned precisely on the workpiece and does not slip. It weighs little and is compactly built so that you can guide it perfectly in mobile use. What's more, the rechargeable battery won't let you down even with frequent use: One charge is enough for more than 800 measurements.

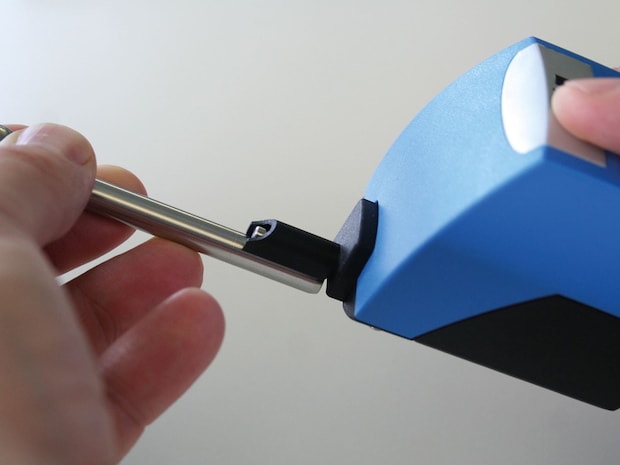

The roughness probes can be changed easily and quickly, meaning the W5 can be used for countless different measuring tasks as required. The intuitive click wheel and color display ensure that you can operate the mobile roughness measuring device particularly easily.

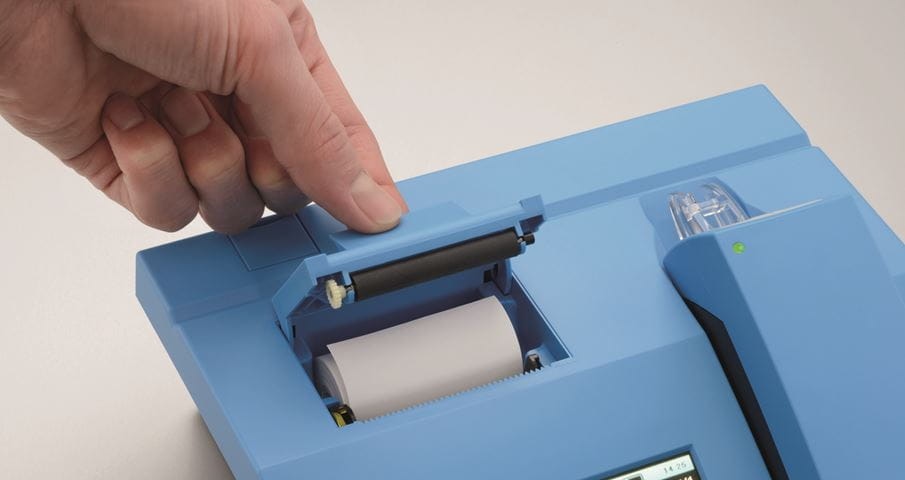

Optionally, you can expand the measuring system with the Waveline P5 printer. The two components are easily connected via Bluetooth® technology. This allows you to print out your measurement results directly on site without the need for any additional connection cables.

System features Waveline W5

- High measurement quality: Mobile device with robust, calibrated roughness probe

- Compact and lightweight: Easily portable thanks to the compact design and weight of just 270 grams

- Durable and wireless: Up to 800 measurements possible with just one battery charge; print out via Bluetooth® technology

- Easy to operate: Intuitive click wheel operation for parameter selection and all device functions

- Clear: Large color display, allowing easy reading of tolerance evaluation results

- Large storage capacity: 5 measuring programs, 100 profiles or 10,000 measurements

- Documentation of the measurement results: Optional printer with Bluetooth® technology for instant printout

- Measurement in all positions: Also on vertical surfaces or in overhead position

- Optional software: Evovis Mobile for direct control in online mode or further processing of measurement data in offline mode

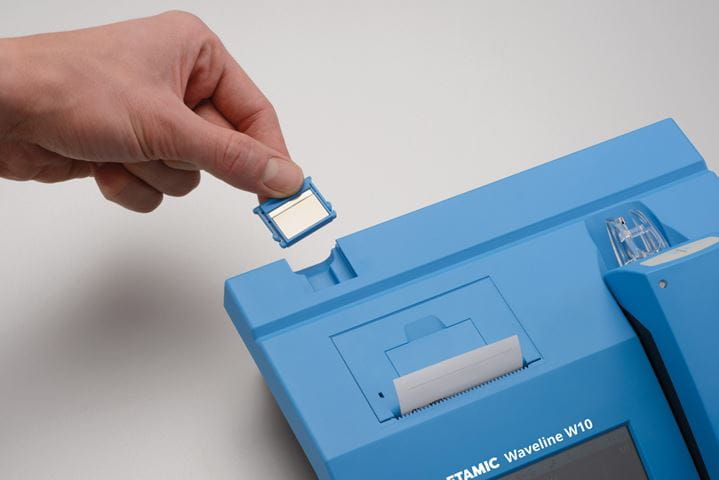

Waveline W10

The Waveline W10 measuring device is ideally suited for mobile roughness measurement. It allows you to monitor the surface quality of your workpieces directly in production. The handy surface roughness measuring system has extensive functions. It offers reliable and precise measurement both during traverse probing and in overhead and vertical positions. The integrated roughness standard is used to quickly check the device and thus ensures consistently high measuring accuracies.

To document the measuring results immediately a thermal printer is integrated in the W10. Tolerance evaluations, profiles, Abbott curves and statistics can be printed out straight away. The measuring device offers you seven different programs as well as the option to test the instrument. All functions can be operated in a user-friendly manner via the modern color touchscreen. No time-intensive training is required, which saves you time and money.

Optionally, you can extend the measuring system with the Evovis Mobile evaluation software. This was specifically developed for mobile measuring devices, is PC-based and considerably expands the roughness measurement functions. It works in online and offline mode and supports you in selecting the measurement conditions. It also automatically saves your print templates.

System features Waveline W10

- Highly precise: Exact measurement of all common roughness parameters

- Compliant with standards: Meets the requirements of international standards

- Versatile: Allows transverse probing, and overhead and vertical measurements

- 90° probe rotation: For measurements on deep surfaces, in grooves, in recesses or between collars

- Practical: Wireless data transmission via Bluetooth® interface; integrated charging station for LV17 feed unit

- Easy to operate: Large, intuitive color touchscreen

- Clear: Results display with tolerance evaluation, surface profiles

- Immediate verification of the device: Integrated roughness standard

- Optional software Evovis Mobile: Online mode for direct control or offline mode for further processing of measurement data

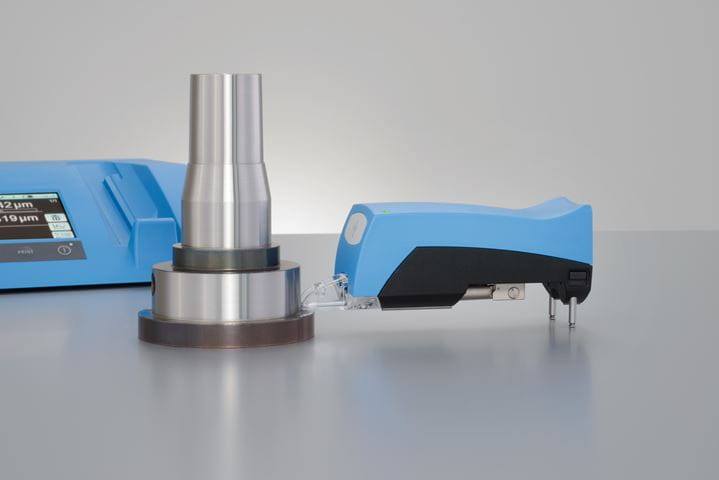

Waveline W15 set with options

With the compact Waveline W15 set, you can measure surface roughness flexibly at the desired location. The handy traverse unit lies securely on the workpiece thanks to the integrated support prism and ensures precise measurements.

The extendable tripod legs and a 3-point support on the traverse unit make it easy to adjust to the desired measuring position, both horizontally and vertically. For measurements on low surfaces, in grooves, in incisions or between collars, the probe can also be swiveled by 90° without any retooling. With a wide range of skid probes, the Waveline W15 set is ready for all common roughness measurement tasks. As an option, the system can easily be extended to create a compact measuring station for production or the measuring room.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the roughness measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features Waveline W15 set

- Practical: Handy traverse unit with integrated start button for one-handed operation

- Wireless: Data transmission via Bluetooth® interface

- Highly precise: All common roughness parameters can be measured exactly

- Compliant with standards: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead, vertically or in transverse probing mode

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

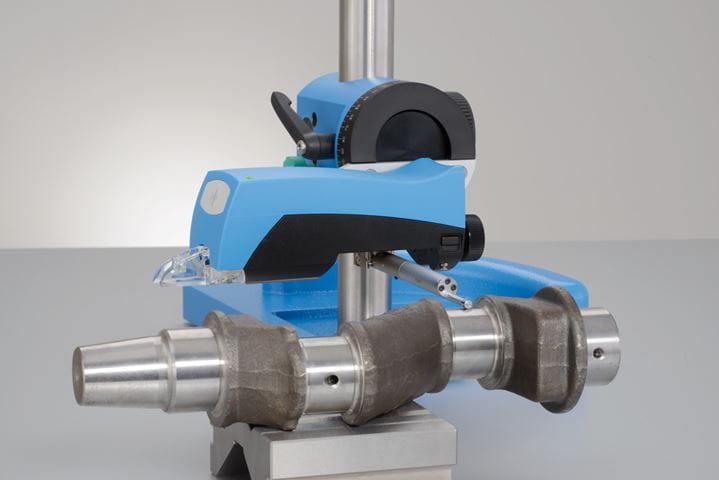

Waveline W40 set with options

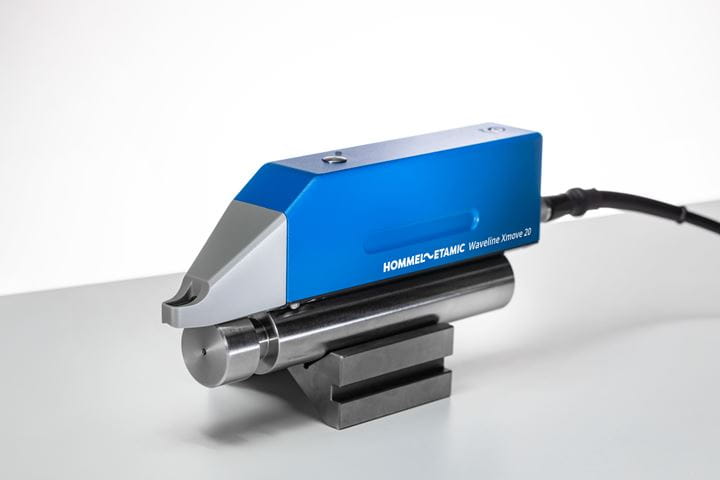

With its handy Waveline Xmove 20 traverse unit, the Waveline W40 set offers flexible options for measuring all common surface roughness, waviness and profile parameters. Operation is simple and intuitive thanks to the integrated start button and motorized probe lowering for automatic positioning of the probe.

The traverse unit masters measurements in all positions and orientations with ease - even overhead with the probes provided for this purpose. It can be optionally used in a compact measuring station or placed directly on a large workpiece for measurement.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear display of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features Waveline W40 set

- Practical: Handy traverse unit with integrated start button for one-handed operation

- Highly precise: All common roughness, waviness and profile parameters can be precisely measured

- Standards-compliant: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead (depending on the probe)

- Comprehensive: Supports a large selection of reference plane and skid probes

- Automatic: Motorized height adjustment for automatic positioning and lifting of the probe tip

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

Waveline W800 & W900

Waveline measuring stations offer maximum flexibility and efficiency in daily measuring practice. They are modular in design and can therefore be easily expanded at a later date. With these systems, you measure surfaces exactly as it fits your individual infrastructure and your specific measurement tasks.

At the same time, the measuring systems are easy to operate and have a wide range of analysis options thanks to the Evovis measuring and evaluation software. Easily interchangeable probe systems and probe arms for roughness and contour measurement ensure flexible application for changing measurement tasks. Depending on the system design, additional evaluations can also be performed as an option, such as 3D topography or twist analysis.

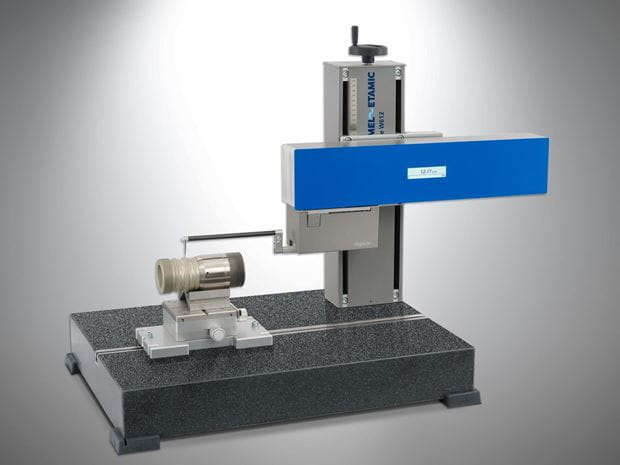

Waveline W600 Digiscan for contour measurement

Waveline W600 roughness and contour measurement systems are easy to operate and, with manual height adjustment, a wide range of mounting options and high measurement quality, are the ideal companion for measurements close to production.

System features Waveline W600

- Universal, easy-to-use measuring system

- High measurement quality thanks to stable mechanics

- Unique traverse concept for optimum accessibility of the measuring points

- Modern touch probes with high resolution

- Interface for probe systems for either roughness or contour measurement with TKU400 or Digiscan probe system

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time due

to automatic probe recognition - Sophisticated probe arm technology

- Probe arms with magnetic coupling for fast and easy probe arm changeover

- All contour probe arms with RFID chip for simplified calibration and automatic configuration

- Measuring points freely accessible thanks to unique traverse unit concept

- Later expansion of the measuring system possible

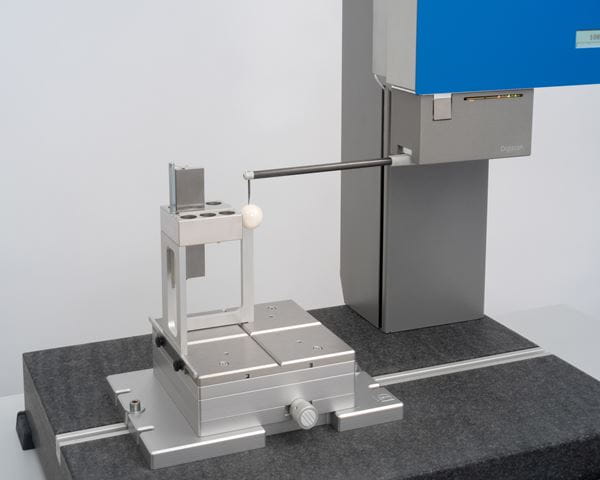

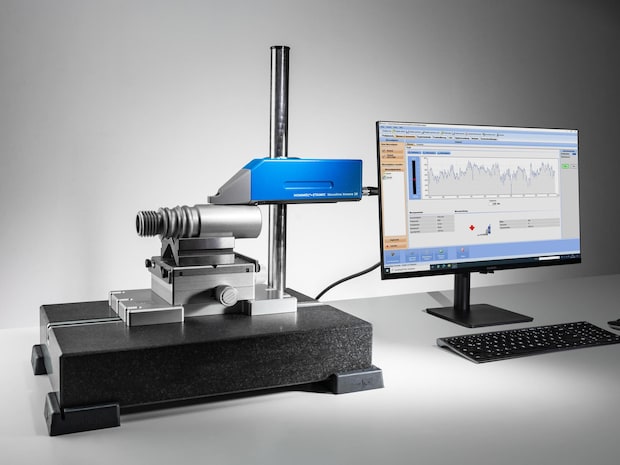

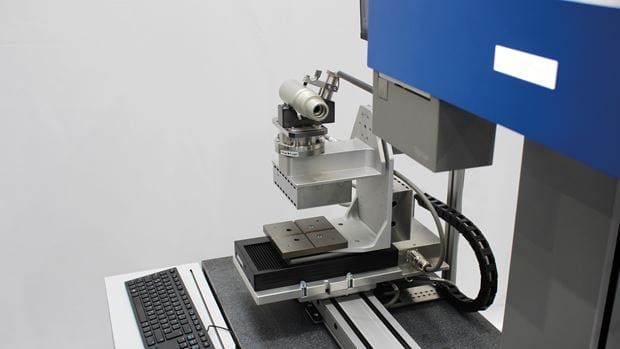

Waveline W800 roughness measurement

Waveline W800 measuring systems have been developed for roughness and contour measuring tasks associated with typically manual or semi-automatic measuring processes. The systems are easy to operate and offer a great variety of analyses thanks to the performant measuring and evaluation software Evovis. The result is the highest standard of measuring accuracy in the shortest time.

The quick-change adapter enables probe systems to be changed over without having to use any tools. Probe arms and probe system are equipped with magnetic coupling making the exchange of probe arms easy and fast. This means you can take a flexible approach towards all of your measuring requirements.

The system automatically detects the intelligent contour probe arms with RFID identification and adjusts the optimal measurement conditions, thus practically eliminating operating errors and incorrect measurements.

System features Waveline W800

- Universal, easy-to-use measuring system

- Modern, high-resolution probe systems

- High measurement quality thanks to stable mechanics

- Sophisticated probe arm technology

- Unique traverse unit concept for optimum access to measuring positions

- Probe arms with magnetic coupling for fast and easy probe arm change over

- All contour probe arms equipped with an RFID chip for simplified calibration and automatic configuration

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time and automatic configuration feature

- Horizontal motion of the probe system occurs via the traverse unit enclosure, meaning the probe arm is always in front of the traverse unit

- Control panel for easy, direct operation of the most important measuring and control functions as well as emergency stop function with restart at interrupted axis position

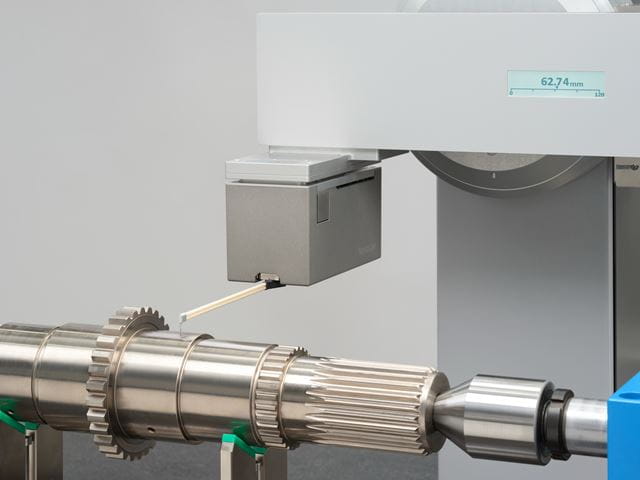

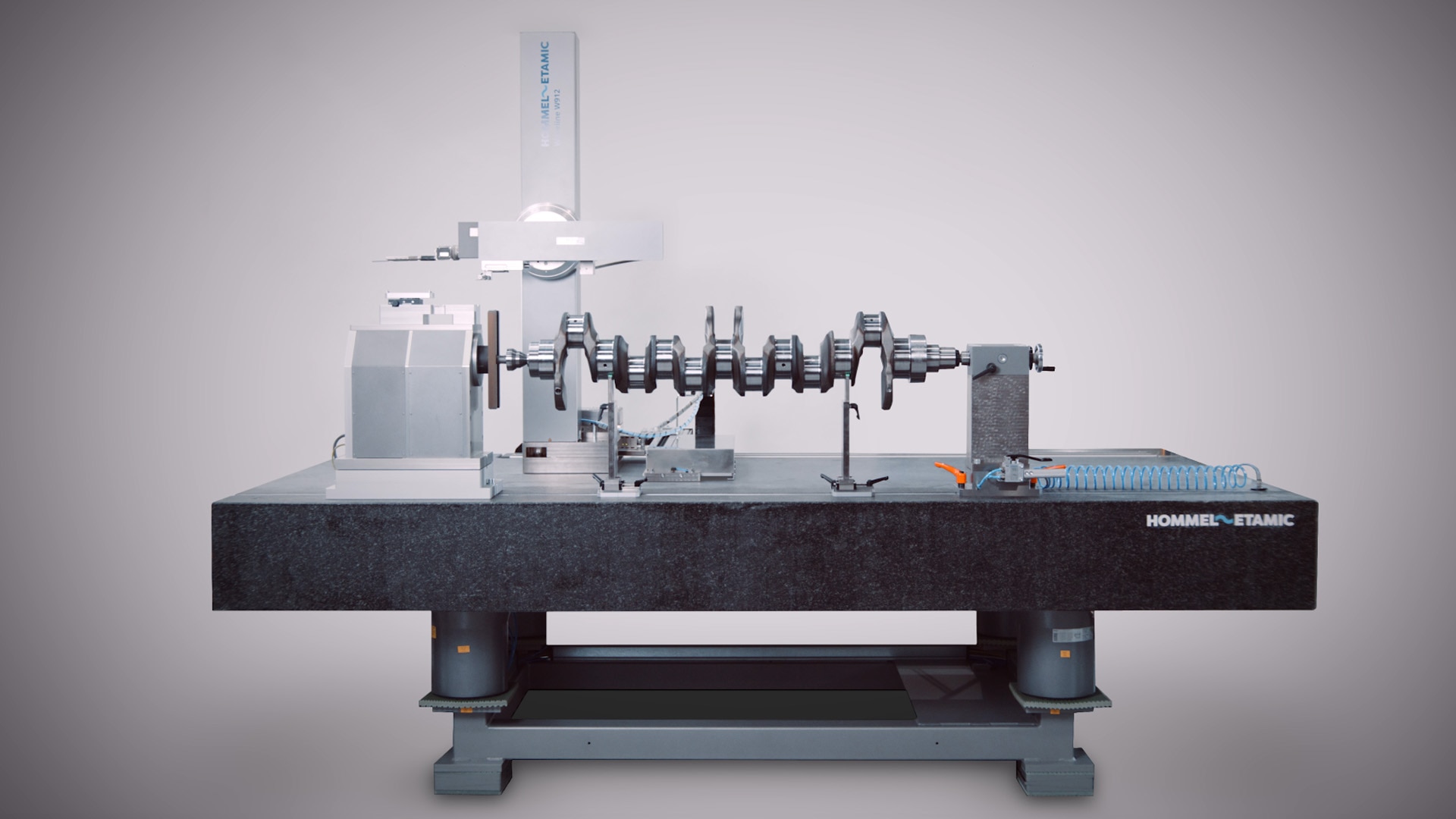

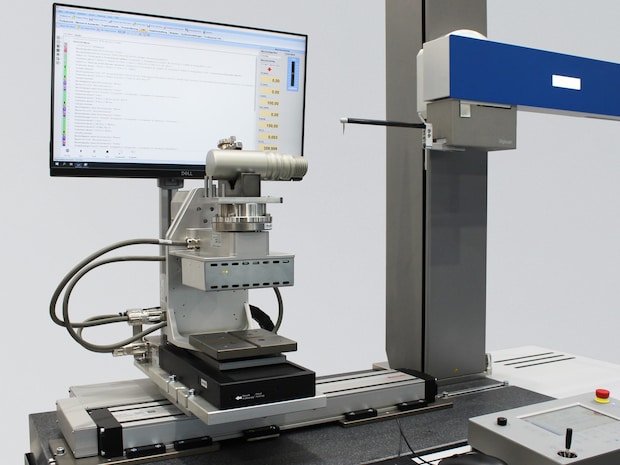

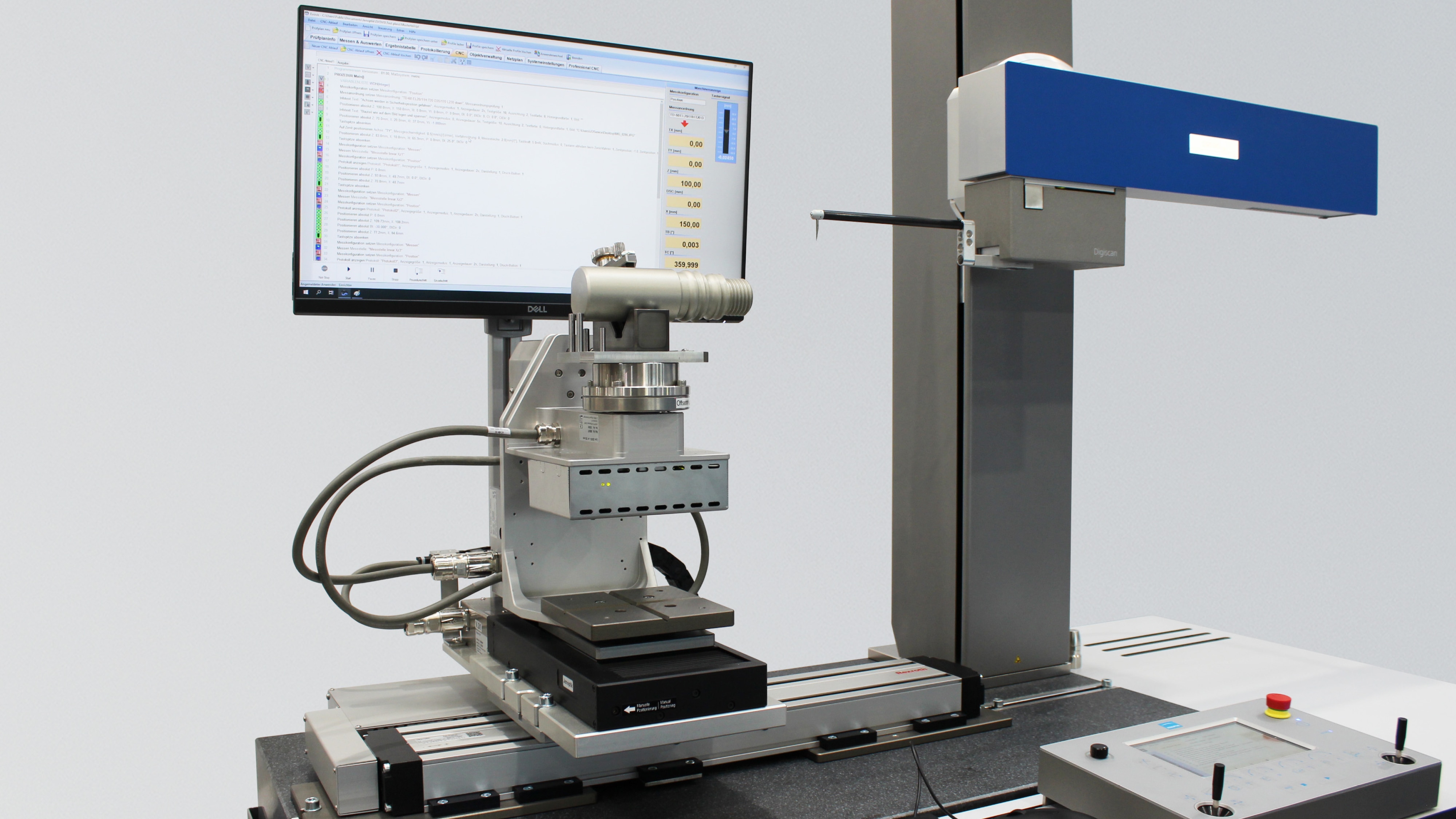

Waveline W900 with instrument table

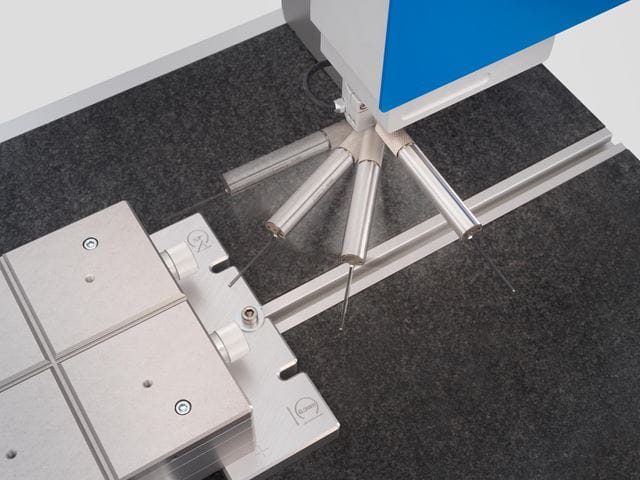

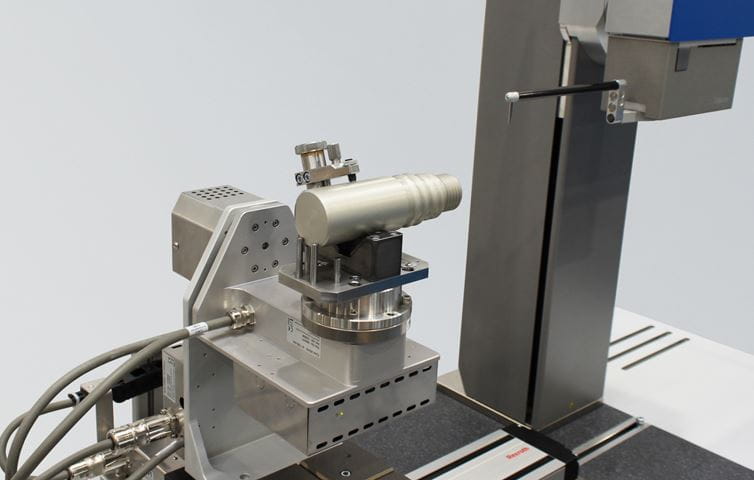

The Waveline W900 series was developed for measuring tasks in high-performance areas, e.g. in the environment of automated process chains. The systems have two interfaces for coupling the touch probes and optionally additional axes for automating measuring sequences. The arrangement of the touch probes and the innovative traverse concept ensure optimum access to the measuring points.

W900 measuring systems are used especially in automated measuring sequences for particularly fast and precise results. With their measuring axes, they guarantee short measuring cycles for complex measuring tasks and thus meet the highest demands on measuring technology. The high-precision traverse unit delivers excellent measuring accuracy in conjunction with the Nanoscan touch probe for combined roughness and contour measurement.

System features Waveline W900

- Fast measurement technology with short cycle times

- Highly flexible, dynamic measurement

- Excellent measuring accuracy in combination with Nanoscan probe system

- Extensive options for automated, CNC-controlled measurement runs

- Dual operation of two probe systems; a roughness probe system can also be installed on the front of the traverse unit; also suitable for optional rotary module

- Optional motorized tilt unit for precise adjustment of the tilt angle and automatic alignment of the probe to the workpiece level

- Measuring Z column with linear scale at a resolution of 0.1 μm for measurement of vertical distances outside the Z measuring range of the probe; requires probe arm with double probe tip

- Additional motorized Y axis or X-Y axis combination for automatic zenith search, topography measurement and workpiece positioning

- Optional rotational axis for roughness measurement on cylindrical workpieces in circumferential and axial direction

Task-specific automation options

Waveline W800 Digiscan measuring station with CNC axes

Fully automatic measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 % inspection of complex components. They are configured workpiece-specifically with CNC axes and fixtures. Thus, the systems perform complex measuring tasks on the respective workpieces fully automatically.

System features CNC axes

- Automated surface measurements for workpiece-specific applications

- Independent, simultaneously operating CNC axes

- Individual fixtures, optionally with automatic identification of the workpiece

- Extensive safety features

- High reliability due to sophisticated technology

- Simple measuring program creation for fully automated processes via Evovis software

- Transfer of measurement results for further processing to statistics programs such as qs-STAT®

Waveline W900 Nanoscan measuring station with cobot

Fully automated measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 % inspection of complex components. With the help of handling systems adapted to the measuring station, not only components are moved, but also probe arms are exchanged according to the measuring task and the measuring program.

System features measuring instruments with handling system

- Fully automatic measurement of roughness and contour in one sequence

- Processing of parts magazines without operator intervention

- Fully automatic probe arm change and recognition

- Positioning of the parts for optimal accessibility of the measuring point

- Interfaces to different measuring and handling systems

Waveline W900 Waveslide

Waveslide measuring stations are individually tailored to suit specific measurement tasks. They are based on proven system components and provide reliable, semi-automatic measurements in the manufacturing environment. These systems are extremely robust and operate with high precision. Workpiece positioning is manual via guided air slides, the measuring process is fully automated.

System features Waveslide

- Manual, simple positioning of the workpiece (alternatively of the measuring column) via air slide

- Guided X-Y positioning via air slide with additional fine adjustment

- Suitable for large and heavy workpieces

- Flexible use for roughness and contour measurement tasks

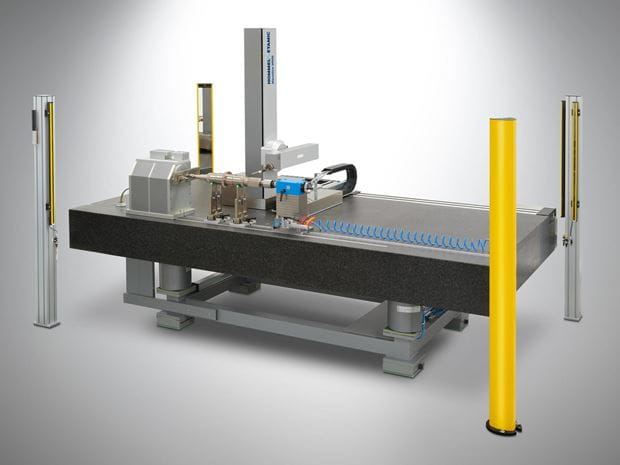

Waveline W900 Wavemove

Wavemove measuring stations offer individual, CNC-controlled, fully automatic roughness and contour measurement on the shop floor. They are based on the W800/W900 platform and are expanded workpiece-specifically with independent CNC axes and workpiece fixtures. This ensures the precise measurement of all required features - completely without operator influence and fully automated.

System features Wavemove

- Automated surface measurements for workpiece-specific applications

- Robust measuring stations suitable for production

- Transfer of measurement results to programs such as the qs-STAT® statistics software

- Flexible system concept for numerous applications

- Simple measurement program creationIndependent, simultaneously operating CNC axes

- Individual workpiece carriers, optionally with automatic identification of the workpiece

- Extensive safety featuresAlso suitable for large and heavy workpieces

EditContact