High-quality form measuring systems for GD&T

Form measuring instruments from HOMMEL ETAMIC check form, position and run-out tolerances of your workpieces – even in tough industrial environments.

We provide you with solutions for a wide range of tasks in form metrology – from the fully automatic CNC measuring machine for all form and positional tolerances to combined form and roughness measuring systems to solutions for large and heavy shafts, e. g. crankshaft or camshaft measurement.

Formline solutions achieve high measurement accuracy even in production environments. At the same time, they are easy to operate thanks to user-friendly software and can be adapted to numerous measuring tasks with a wide range of accessories.

Individual form measuring systems for your requirements

For special requirements, we develop measuring systems that are specially tailored to your needs. You benefit from our extensive knowledge in the development of special solutions - for example for brake discs.

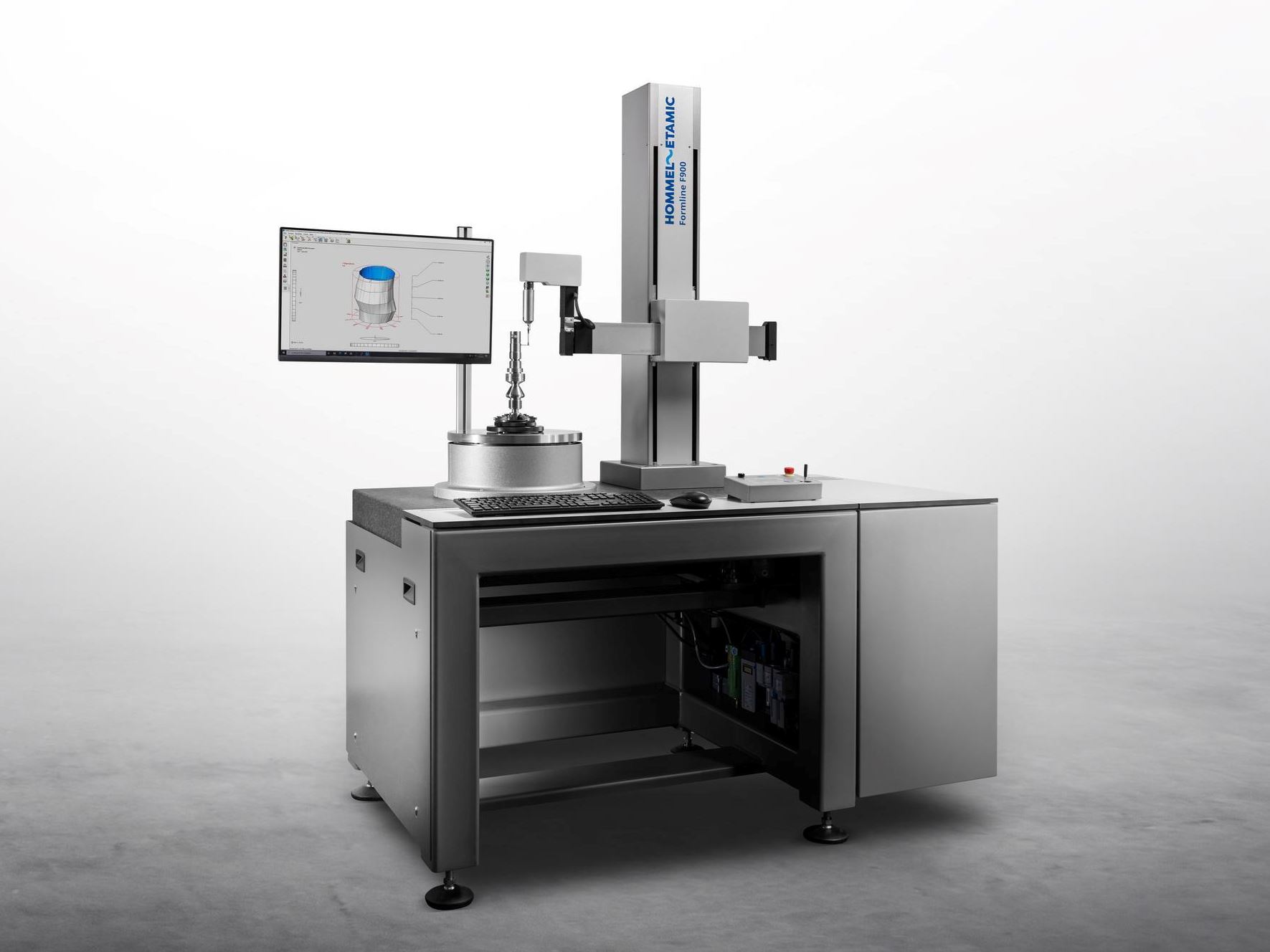

Discover now: Formline F900

Our form measuring systems offer a highly efficient solution for form, roughness and twist measurement. They are equipped with a high-precision rotary table with air bearings and are extremely robust. They are suitable both for measuring tasks in series production and for use in the measuring room with frequently changing measuring tasks.

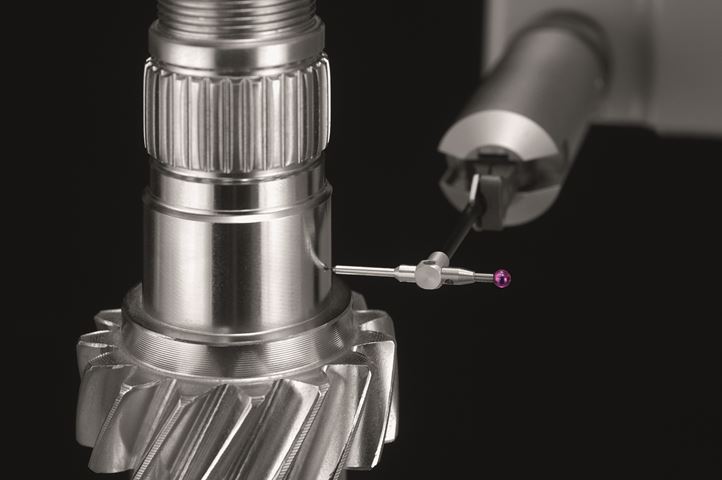

The systems offer a high degree of automation with automatic workpiece alignment and CNC-controlled measuring axes. With the optional tilt and rotation module, even hard-to-reach probing positions are reached without interrupting the CNC run.

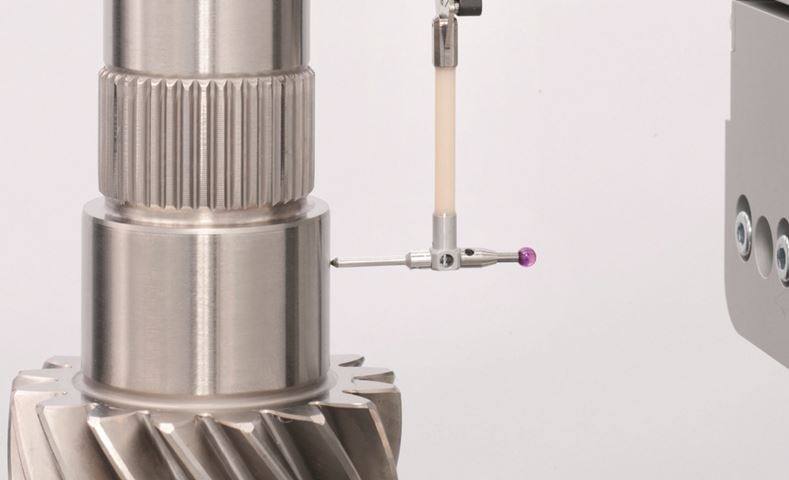

Equipped with an optional double-tipped probe arm, the CNC measuring instruments also perform roughness, waviness and twist measurements – all in one setup.

- Measurement of form, run-out and position tolerances, for example roundness, flatness, cylindricity or total radial run-out

- Determination of specific characteristics such as conicity, crowning or dominant roundness waviness

- Optional roughness, waviness and twist measurement

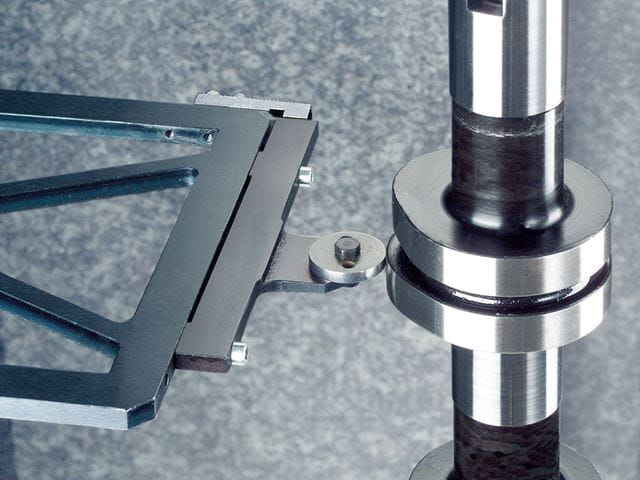

- Magnetic probe coupling for fast probe arm changes

- Convertible, double-tipped probe system for form and roughness

Formline F900 | Precise and automated measurements in quality control

Highlights

- Time saving thanks to very fast, fully automatic centering and leveling and CNC controlled measuring axes

- Flexible use with free probe system in C, Z and R direction for form, roughness, waviness and twist measurement in a single clamping operation

- Heights of vertical measuring axis: 350, 550 or 900 mm

- Vibration-damped instrument table with container for PC and system electronics

- Magnetic probe arm coupling for fast changing of the probe arm and protection in case of collisions

- Flexible access to external/internal measurement positions thanks to fully automatic probe positioning, fully automatic, freely adjustable probe force and reversible scanning direction

System features

- Highly accurate air bearing rotary table with outstanding rigidity for consistently high precision

- High resolution with 0.1 µm in the R/Z axis and 360,000 points in the C axis

- Integrated linear scale and active level control

- CNC controlled motorized tilt and rotation module for fully automatic measurements

- Double-tipped probe system can be switched from form to roughness during the CNC run

- For roughness measurement, the probing force can be programmed in any position of the probe arm in accordance with standards

- Axes with high resolution and very low interference

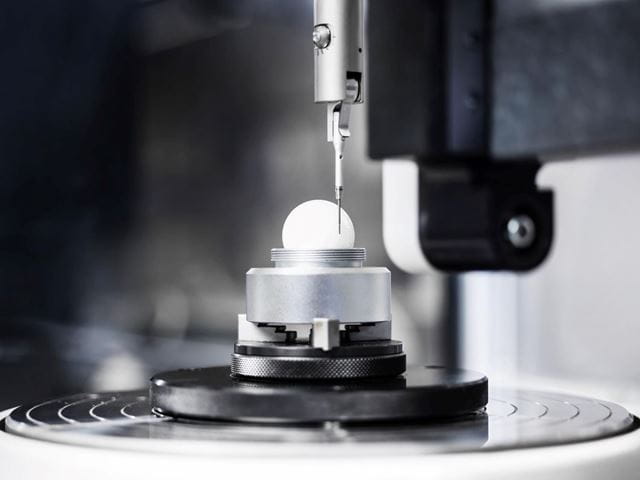

- Automatic zenith alignment of the probe arm through 3-ball system

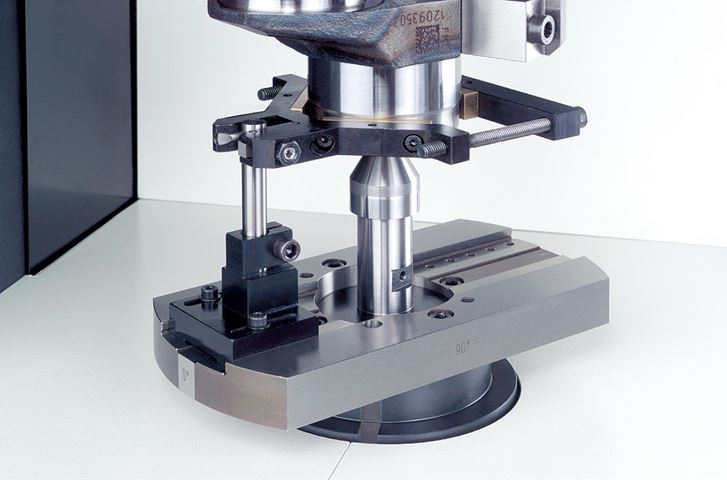

Application brake disc measurement

Formline CFM3010

The fully automatic, high-resolution Formline CFM3010 measuring system flexibly and reliably determines form and position deviations of different workpiece types. Thanks to its outstanding basic accuracy and robust design with vibration decoupling, the system is suitable for use in the measuring room or in the production environment.

Optimized CNC processes in conjunction with high measurement and travel speeds as well as fast measurement value recording ensure short measuring cycles.

Extensive accessories such as followers and drivers ensure safe handling of complex workpieces.

Benefits

- Precise: high-resolution measuring system for exact results

- Reliable measurement results: no mechanical transverse forces

- Constant: repetitive accuracy of up to 0.3 µm

- Reliable analysis: detection of form and dimensional deviations using the Turbo Shaft software

- Robust: suitable for use in metrology lab and production environments

EditContact