用于测量轮廓和粗糙度的测量仪

使用我们的测量仪,您可以在单个探测步骤或单独的测量运行中测量组件的粗糙度和轮廓。

Our product range consists of mobile surface measuring instruments, stationary measuring systems for manual and automated roughness, contour, topography or twist measurement, as well as combined systems for roughness and contour measurements. We also offer measuring stations tailored to your specific measuring requirements.

Waveline solutions are the result of our years of experience and comprehensive know-how and can be configured for different measuring tasks depending on the requirements.

Our measuring systems operate with high precision and reliability in accordance with current standards. They are easy to operate and are ideally suited for daily use on the shop floor and in the metrology lab.

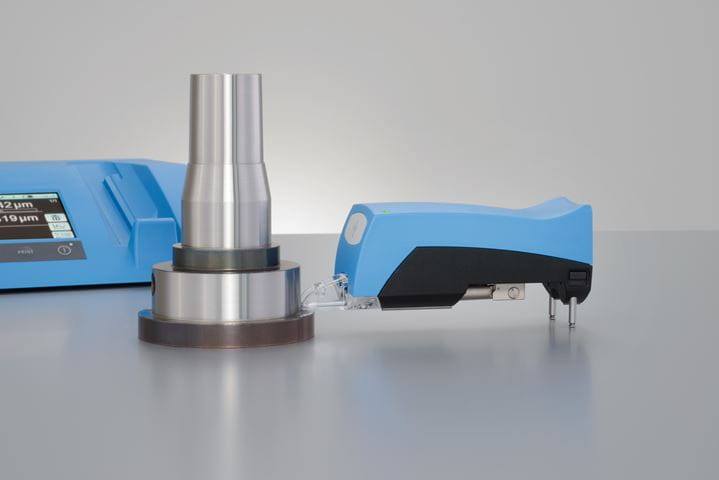

您可以使用触觉粗糙度测量方法测量工件的表表面纹理。可使用各种各样的测量系统 - 从适用于移动应用场合的紧凑型便携式测量仪,到适用于执行复杂测量任务的固定式系统,再到客户定制的专用测量站。

我们的粗糙度测量仪高度精密、可靠。非常适合日常用于生产环境中,且操作简单,可节省您的时间、成本和资源。我们拥有多年的经验和广泛的专业知识,这意味着我们非常熟悉客户的不同需求。我们很乐意针对您的工件测量任务,定制粗糙度测量系统。

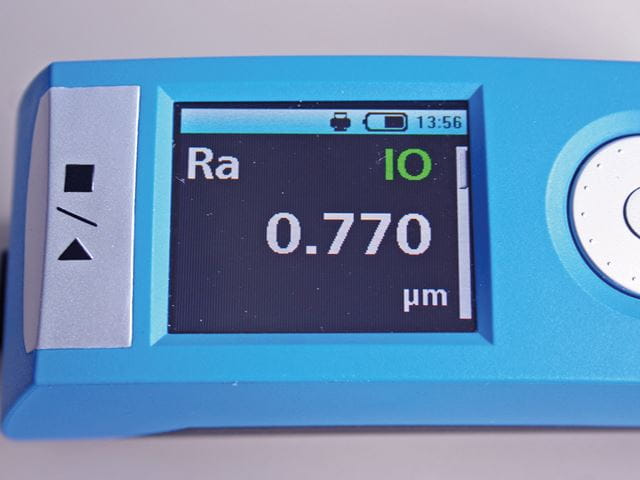

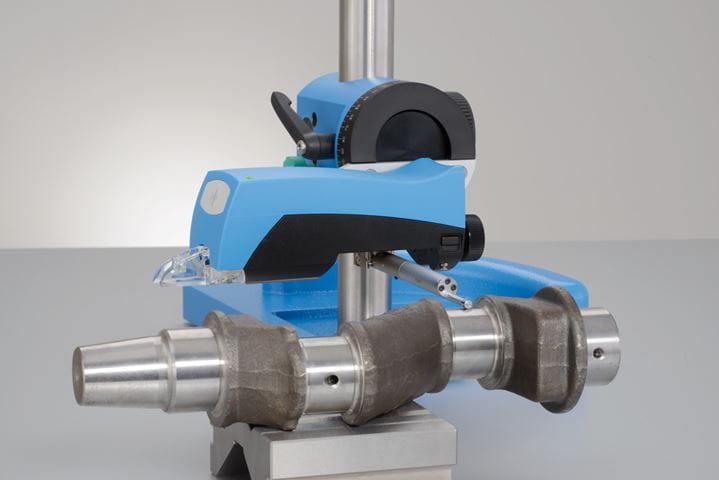

The portable measuring instrument Waveline W5 is easy to use, robust and delivers reliable results – due to it's compact and light design the W5 is perfect for mobile use.

Waveline W5 with printer

Waveline W5 移动式测量仪的粗糙度测量可靠且高度精密,令人印象深刻。系统可以精确定位在工件上,而且不会滑动。它的重量很轻,采用紧凑设计,这意味可将其轻松用于移动应用场合。该测量仪配备电池组,这意味着即使频繁使用也不会让您失望:可为超过 800 次测量持续提供电力。

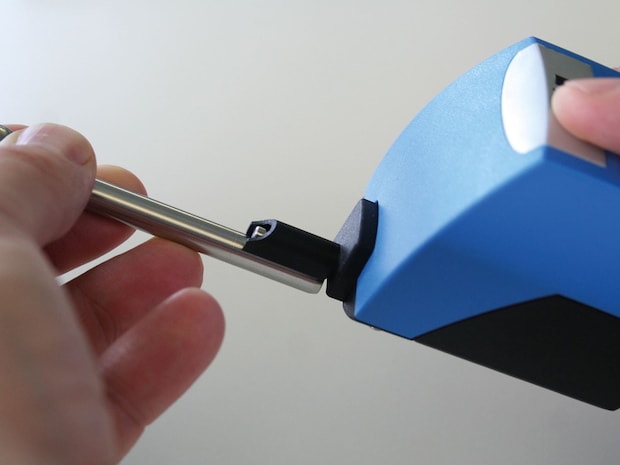

可以轻松快捷地更换粗糙度探头(测量探头),这意味着 W5 可以用于执行无数不同的测量任务。该测量仪采用直观的触控式滚轮和彩色显示屏,使用起来非常容易。

此外,还可以选择使用 Waveline P5 打印机扩展该测量系统。这两个组件可以通过最新的蓝牙 (Bluetooth®) 技术轻松相连,让您可以在现场打印出测量结果,而无需任何额外的连接电缆。

优点

- 高测量质量:坚固耐用、 已校准的粗糙度探头

- 紧凑且重量轻:采用紧凑设计且重量只有 270 克,因此非常便于携带

- 持久耐用且采用无线方式:只需充满电就可以最多进行 800 次测量;可通过蓝牙 (Bluetooth®) 技术打印出测量结果

- 易用:直观的图形用户界面和触控式滚轮

- 清晰:宽大的彩色显示屏,可轻松读取公差评价结果

- 存储器容量大:5 个测量程序,100 个轮廓或 10,000 次测量

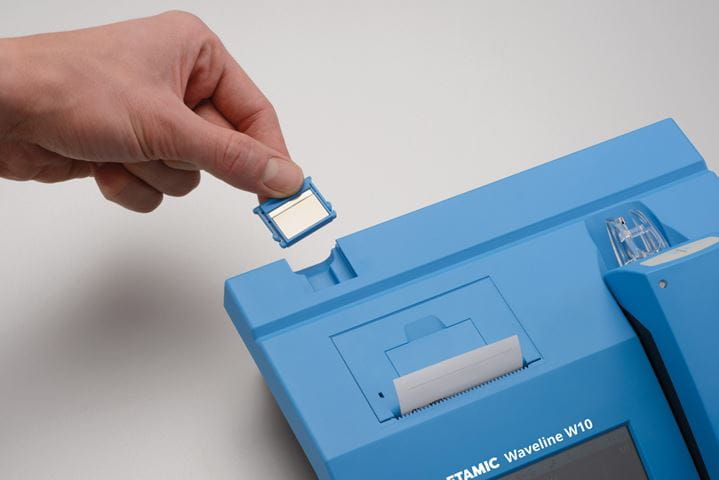

借助移动式 Waveline W10 测量仪,您可以用无线方式测量工件,清晰的测量结果始终显示在宽大的触摸屏上。

Waveline W10

Waveline W10 测量仪非常适合用于进行移动式粗糙度测量,让您可以在生产过程本身中监测工件的表面质量。这款实用的测量系统具有广泛的功能。它在横向探测期间以及架空位置和垂直位置中提供可靠且精密的测量。集成的粗糙度标准支持快速测试测量仪,确保始终获得非常高的精密度。

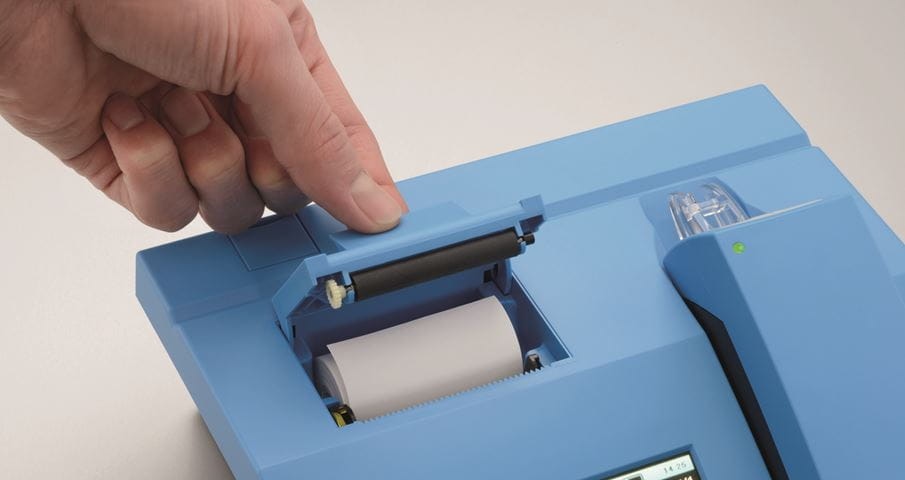

W10 具有集成的热敏式打印机,这意味着可以立即记录测量结果。可以立即打印出公差评估、轮廓、Abbott 曲线和统计数据。该测量仪提供了七个不同的程序,以及用于测试测量仪的选项。所有功能均可通过现代且易于使用的彩色触摸屏进行操作。无需进行长时间的培训,因此可节省您的时间和资金。

此外,还可以选择使用 EVOVIS 移动评估软件扩展该测量系统。这款基于 PC 的软件是专门为移动式测量仪开发的,极大地扩展了粗糙度测量功能。它以在线和离线模式运行,支持您选择测量条件。您还可以自动保存打印表格。

优点

- 高精度:精密测量所有常见的粗糙度参数

- 符合标准:满足国际标准的要求

- 多功能:支持进行横向探测以及架空位置和垂直位置的测量

- 实用:以无线的方式进行测量;LV17 扫描单元集成充电座

- 易用:直观、现代的触摸屏

- 清晰:具有公差评估和表面轮廓的结果视图

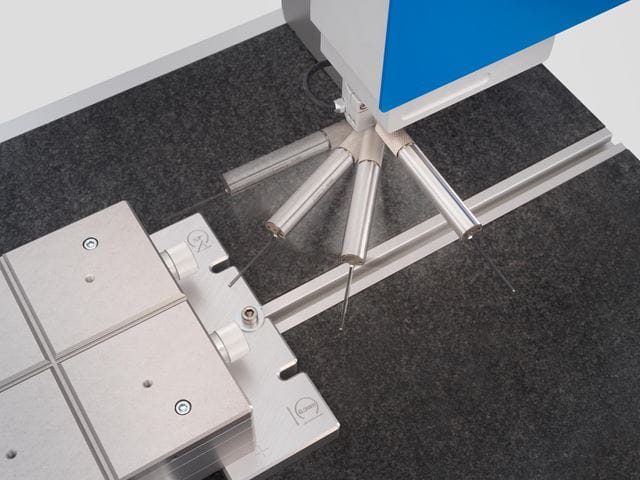

Waveline W15 set with options

With the compact Waveline W15 set, you can measure surface roughness flexibly at the desired location. The handy traverse unit lies securely on the workpiece thanks to the integrated support prism and ensures precise measurements.

The extendable tripod legs and a 3-point support on the traverse unit make it easy to adjust to the desired measuring position, both horizontally and vertically. For measurements on low surfaces, in grooves, in incisions or between collars, the probe can also be swiveled by 90° without any retooling. With a wide range of skid probes, the Waveline W15 set is ready for all common roughness measurement tasks. As an option, the system can easily be extended to create a compact measuring station for production or the measuring room.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the roughness measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features Waveline W15 set

- Practical: Handy traverse unit with integrated start button for one-handed operation

- Wireless: Data transmission via Bluetooth® interface

- Highly precise: All common roughness parameters can be measured exactly

- Compliant with standards: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead, vertically or in transverse probing mode

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

Waveline W40 set with options

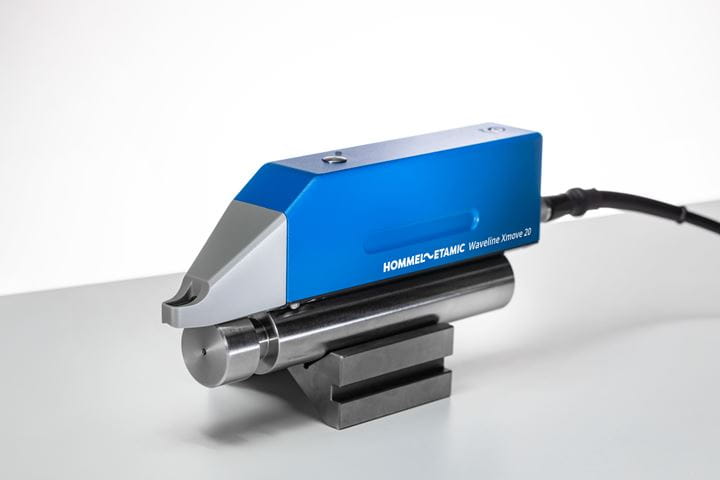

With its handy Waveline Xmove 20 traverse unit, the Waveline W40 set offers flexible options for measuring all common surface roughness, waviness and profile parameters. Operation is simple and intuitive thanks to the integrated start button and motorized probe lowering for automatic positioning of the probe.

The traverse unit masters measurements in all positions and orientations with ease - even overhead with the probes provided for this purpose. It can be optionally used in a compact measuring station or placed directly on a large workpiece for measurement.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear display of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features Waveline W40 set

- Practical: Handy traverse unit with integrated start button for one-handed operation

- Highly precise: All common roughness, waviness and profile parameters can be precisely measured

- Standards-compliant: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead (depending on the probe)

- Comprehensive: Supports a large selection of reference plane and skid probes

- Automatic: Motorized height adjustment for automatic positioning and lifting of the probe tip

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

产品预览

Waveline W800 & W900

Waveline measuring stations offer maximum flexibility and efficiency in daily measuring practice. They are modular in design and can therefore be easily expanded at a later date. With these systems, you measure surfaces exactly as it fits your individual infrastructure and your specific measurement tasks.

At the same time, the measuring systems are easy to operate and have a wide range of analysis options thanks to the Evovis measuring and evaluation software. Easily interchangeable probe systems and probe arms for roughness and contour measurement ensure flexible application for changing measurement tasks. Depending on the system design, additional evaluations can also be performed as an option, such as 3D topography or twist analysis.

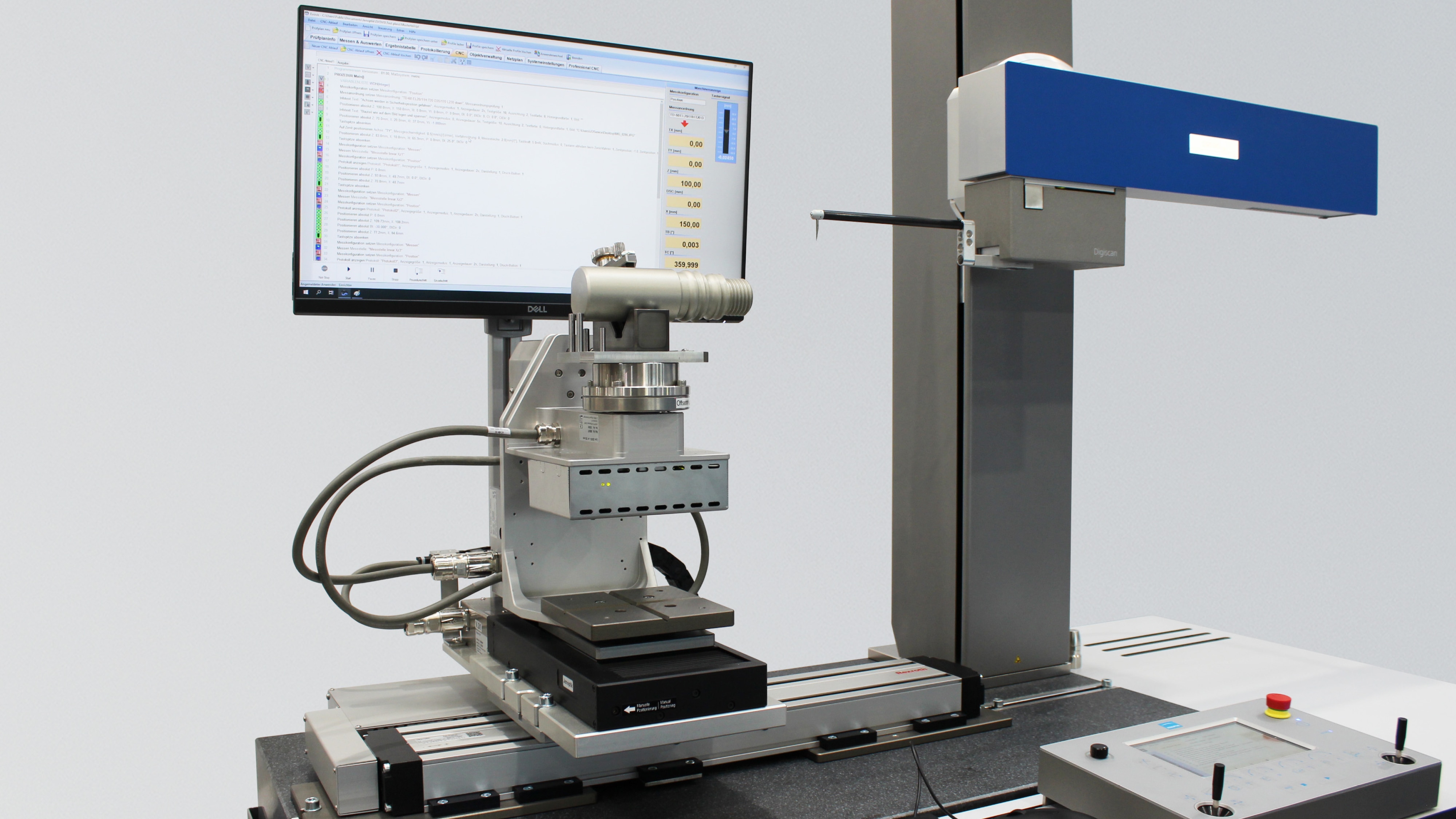

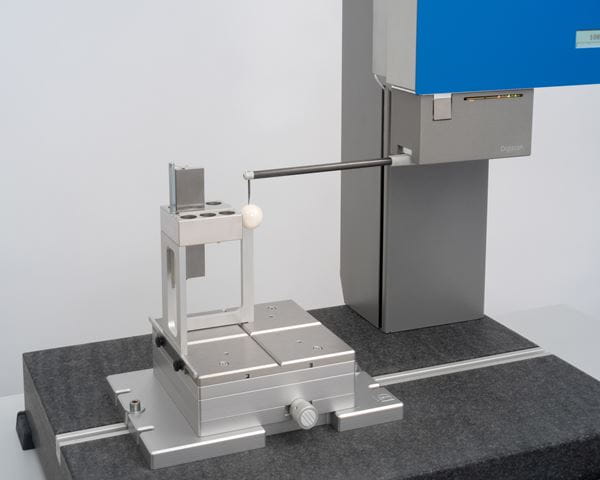

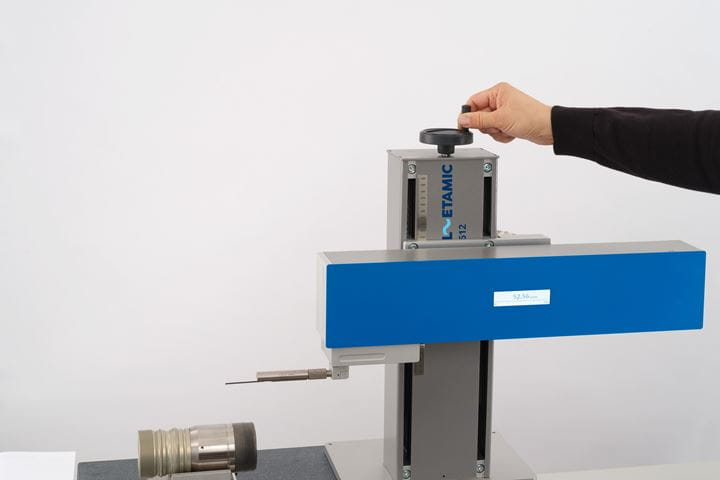

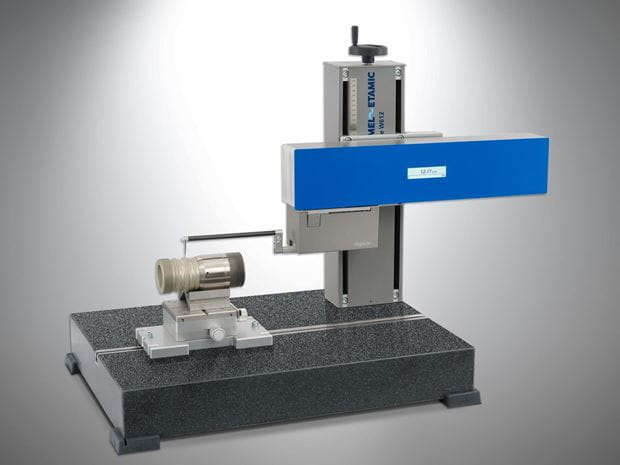

Waveline W600 Digiscan for contour measurement

Waveline W600 roughness and contour measurement systems are easy to operate and, with manual height adjustment, a wide range of mounting options and high measurement quality, are the ideal companion for measurements close to production.

System features Waveline W600

- Universal, easy-to-use measuring system

- High measurement quality thanks to stable mechanics

- Unique traverse concept for optimum accessibility of the measuring points

- Modern touch probes with high resolution

- Interface for probe systems for either roughness or contour measurement with TKU400 or Digiscan probe system

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time due

to automatic probe recognition - Sophisticated probe arm technology

- Probe arms with magnetic coupling for fast and easy probe arm changeover

- All contour probe arms with RFID chip for simplified calibration and automatic configuration

- Measuring points freely accessible thanks to unique traverse unit concept

- Later expansion of the measuring system possible

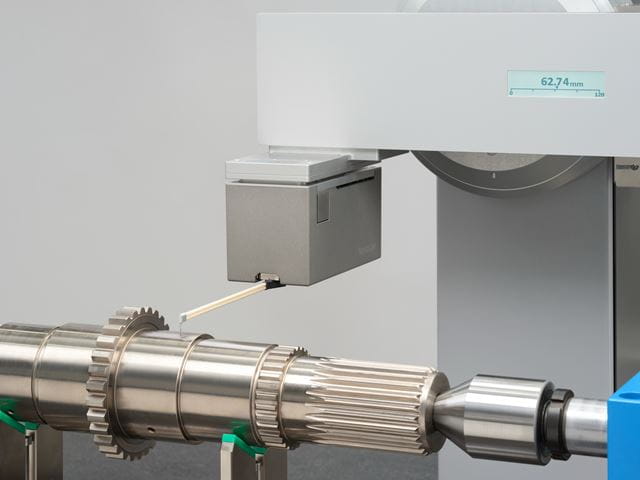

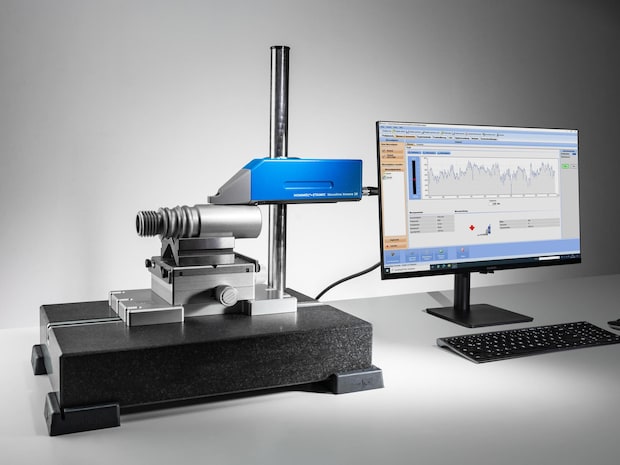

Waveline W800 roughness measurement

Waveline W800 measuring systems have been developed for roughness and contour measuring tasks associated with typically manual or semi-automatic measuring processes. The systems are easy to operate and offer a great variety of analyses thanks to the performant measuring and evaluation software Evovis. The result is the highest standard of measuring accuracy in the shortest time.

The quick-change adapter enables probe systems to be changed over without having to use any tools. Probe arms and probe system are equipped with magnetic coupling making the exchange of probe arms easy and fast. This means you can take a flexible approach towards all of your measuring requirements.

The system automatically detects the intelligent contour probe arms with RFID identification and adjusts the optimal measurement conditions, thus practically eliminating operating errors and incorrect measurements.

System features Waveline W800

- Universal, easy-to-use measuring system

- Modern, high-resolution probe systems

- High measurement quality thanks to stable mechanics

- Sophisticated probe arm technology

- Unique traverse unit concept for optimum access to measuring positions

- Probe arms with magnetic coupling for fast and easy probe arm change over

- All contour probe arms equipped with an RFID chip for simplified calibration and automatic configuration

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time and automatic configuration feature

- Horizontal motion of the probe system occurs via the traverse unit enclosure, meaning the probe arm is always in front of the traverse unit

- Control panel for easy, direct operation of the most important measuring and control functions as well as emergency stop function with restart at interrupted axis position

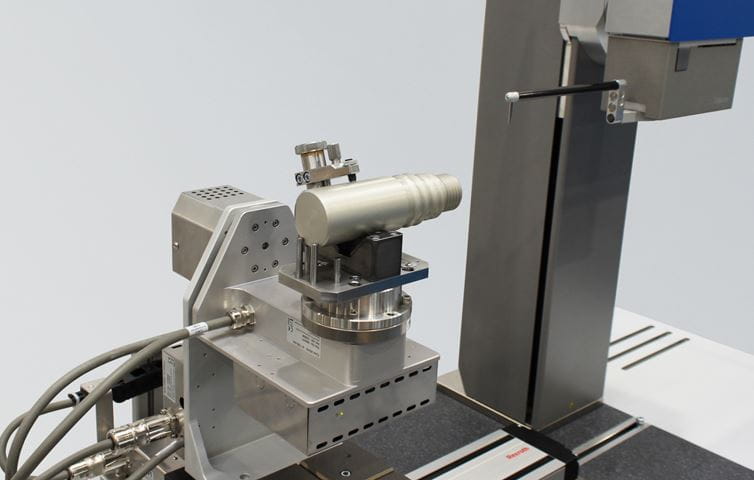

Waveline W900 with instrument table

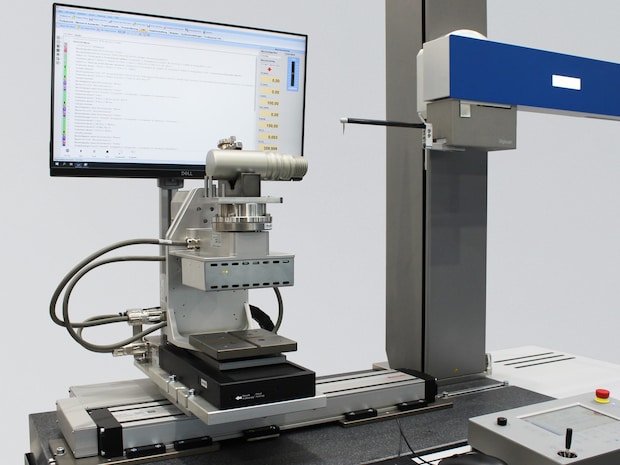

The Waveline W900 series was developed for measuring tasks in high-performance areas, e.g. in the environment of automated process chains. The systems have two interfaces for coupling the touch probes and optionally additional axes for automating measuring sequences. The arrangement of the touch probes and the innovative traverse concept ensure optimum access to the measuring points.

W900 measuring systems are used especially in automated measuring sequences for particularly fast and precise results. With their measuring axes, they guarantee short measuring cycles for complex measuring tasks and thus meet the highest demands on measuring technology. The high-precision traverse unit delivers excellent measuring accuracy in conjunction with the Nanoscan touch probe for combined roughness and contour measurement.

System features Waveline W900

- Fast measurement technology with short cycle times

- Highly flexible, dynamic measurement

- Excellent measuring accuracy in combination with Nanoscan probe system

- Extensive options for automated, CNC-controlled measurement runs

- Dual operation of two probe systems; a roughness probe system can also be installed on the front of the traverse unit; also suitable for optional rotary module

- Optional motorized tilt unit for precise adjustment of the tilt angle and automatic alignment of the probe to the workpiece level

- Measuring Z column with linear scale at a resolution of 0.1 μm for measurement of vertical distances outside the Z measuring range of the probe; requires probe arm with double probe tip

- Additional motorized Y axis or X-Y axis combination for automatic zenith search, topography measurement and workpiece positioning

- Optional rotational axis for roughness measurement on cylindrical workpieces in circumferential and axial direction

使用业纳测量仪可以测量工件的粗糙度和轮廓。您在一个测量系统中获得两个探测系统。这两个探测系统可以彼此独立地使用,从而节省您的时间和资金。

测量运行基本上是自动化的。运用新的 RFID 技术,我们的一些测量仪甚至可以检测到正在使用哪个探臂,并相应地设置测量条件。探臂以磁力连接,这意味着可以快速且安全地更换探臂。因此,您可以轻松调节测量系统以适应每个新的测量任务,从而获得重复精度和高精度的测量结果。

这些测量仪采用模块化设计,因此可以轻松扩展。此外,系统坚固耐用。系统即使在恶劣的生产环境下也能毫无故障地运行,因此非常适合用于艰苦的工业环境。

Task-specific automation options

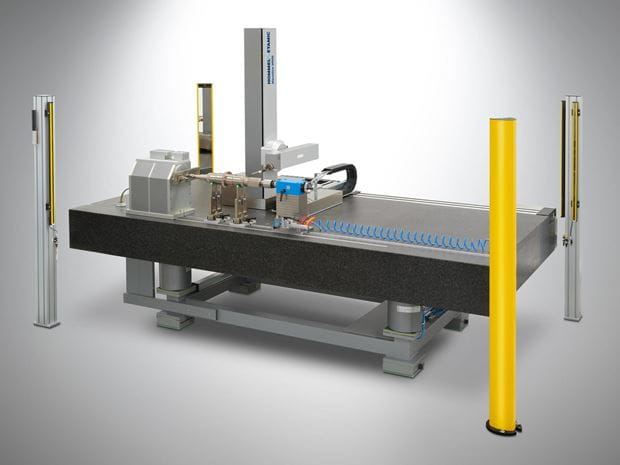

Waveline W800 Digiscan measuring station with CNC axes

Fully automatic measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 % inspection of complex components. They are configured workpiece-specifically with CNC axes and fixtures. Thus, the systems perform complex measuring tasks on the respective workpieces fully automatically.

System features CNC axes

- Automated surface measurements for workpiece-specific applications

- Independent, simultaneously operating CNC axes

- Individual fixtures, optionally with automatic identification of the workpiece

- Extensive safety features

- High reliability due to sophisticated technology

- Simple measuring program creation for fully automated processes via Evovis software

- Transfer of measurement results for further processing to statistics programs such as qs-STAT®

Waveline W900 Nanoscan measuring station with cobot

Fully automated measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 % inspection of complex components. With the help of handling systems adapted to the measuring station, not only components are moved, but also probe arms are exchanged according to the measuring task and the measuring program.

System features measuring instruments with handling system

- Fully automatic measurement of roughness and contour in one sequence

- Processing of parts magazines without operator intervention

- Fully automatic probe arm change and recognition

- Positioning of the parts for optimal accessibility of the measuring point

- Interfaces to different measuring and handling systems

Waveline W900 Waveslide

Waveslide measuring stations are individually tailored to suit specific measurement tasks. They are based on proven system components and provide reliable, semi-automatic measurements in the manufacturing environment. These systems are extremely robust and operate with high precision. Workpiece positioning is manual via guided air slides, the measuring process is fully automated.

System features Waveslide

- Manual, simple positioning of the workpiece (alternatively of the measuring column) via air slide

- Guided X-Y positioning via air slide with additional fine adjustment

- Suitable for large and heavy workpieces

- Flexible use for roughness and contour measurement tasks

Waveline W900 Wavemove

Wavemove measuring stations offer individual, CNC-controlled, fully automatic roughness and contour measurement on the shop floor. They are based on the W800/W900 platform and are expanded workpiece-specifically with independent CNC axes and workpiece fixtures. This ensures the precise measurement of all required features - completely without operator influence and fully automated.

System features Wavemove

- Automated surface measurements for workpiece-specific applications

- Robust measuring stations suitable for production

- Transfer of measurement results to programs such as the qs-STAT® statistics software

- Flexible system concept for numerous applications

- Simple measurement program creationIndependent, simultaneously operating CNC axes

- Individual workpiece carriers, optionally with automatic identification of the workpiece

- Extensive safety featuresAlso suitable for large and heavy workpieces